Schuon

New MX-X scores at first serve

Industry: Logistics

Company: 120 employees, sites in Haiterbach (headquarters) and Lengwil

Challenge: Maximum flexibility in volatile product and demand fluctuations and a fragile assortment of 180,000 articles.

The solution: Racking system for 65,000 pallets for high utilisation of warehouse space. Rack heights of 17.2 metres Optimised storage and retrieval times.

STILL products: MX-X VNA trucks, FM-X reach trucks with active load stabilisation (ALS).

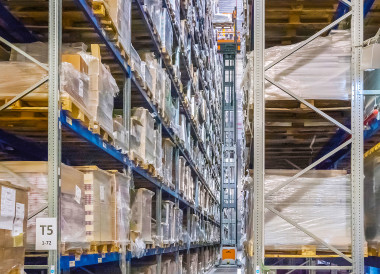

The logistics service provider Schuon uses the complete volume of the warehouse building right to the ceiling. In the large hall, MX-X VNA trucks store and retrieve from 17-metre high racks. With the triplex standard of the trucks of the new series, such heights are easy to master. The effective reduction of oscillations of the mast and the simultaneous main and auxiliary lift of the turret head effectively save time for storage and retrieval. Due to optimised cabin ergonomics and better oscillation behaviour, the pick rate could also be increased.

Modern warehousing in the Black Forest

With 140,000 pallet bays, 80,000 order pick bays and 10,000 square metres outdoor storage area, Gebrüder Schuon Logistik GmbH operates an economic distribution centre in the Swabian town Haiterbach. Clocked for “Just in Sequence” supply, quality management and stock planning for procurement logistics or fulfilment for online shops: The logistics expert runs modern warehousing in all its variants in the Black Forest. “The main reserve warehouse currently mainly stores books. But tomorrow, it could be completely different articles. To allow maximum reactivity to volatile product and demand fluctuations, we operate warehouse equipment that is customised to our demand”, the company owner and managing director, Horst Schuon, explains. With respect to warehousing, the sensitive assortment of 180,000 articles requires absolutely gentle handling and greatest care. After the building of the hall, the intralogistics expert STILL from Hamburg was ordered to install the racking system for 65,000 pallets. The 17.2-metre high racks with 30 aisles are flexibly operated with warehouse trucks. “Against the background of our good partnership, STILL has been taking care of our warehouse fleet for many years in full-service”, Horst Schuon adds.

MX-X Triplex standard: Storage height up to 18 metres

In the main hall, the top of the racks is operated by rail-guided MX-X VNA trucks. For such heights, STILL used to design the triplex mast as a special customer version. On the new MX-X, the closed height of the standard triplex mast is already 6.90 metres. Together with the auxiliary lift, storage heights of up to 18 metres are easy to reach. Wide cross beams and bracings on both sides increase the ruggedness of the mast and reduce mast deflection.

Faster storage processes by stabilising the load

Efficient and fast warehouse processes are crucial for the business of the logistics service provider. A stabilisation system similar to the ALS system STILL provides for the FM-X reach truck, controlled hydraulic movements compensate oscillations of the mast when storing and retrieving loads. Other than the ALS system, this system does not measure the movement of the mast. The on-board controller only needs the lift height and the load weight. With this data, the on-board computer calculates the deflection of the mast and compensates the movement of the mast by reducing reach speed and distance. This effectively saves time during storage and retrieval.

Optimised cabin ergonomics and reduced oscillations increase the pick speed

Every week, up to 20,000 shipments are delivered. With the growth of online-business, batch sizes shrink from pallet size to smaller and smaller lots that are picked from pallets. The new MX-X reacts to this development with an optimised cabin for better ergonomics. The compact redesign of the turret head was not only improved in terms of stability of the auxiliary lift, but also the distance between the cabin and the pallet was reduced by 40 millimetres. Also, the depth of the cabin was increased by 50 millimetres. The front window which was extended downwards by 80 millimetres improved the visibility of the forks when the operator is seated. Now, it is possible to pick up and place pallets without having to stand up. “With our drivers, the tilting barrier is also very popular. It reduces the distance to the rack so that especially small drivers can reach further in”, Schuon adds. Besides this, the mount of the cabin was further improved to reduce swinging movements of the pallet when order picking from pallets. Thanks to the now more comfortable order picking, these optimisations eventually increase the pick speed.

Simultaneous movements of main and auxiliary lift of the new turret head reduce access times

Short access times are key to fast order picking. “As a result of the simultaneous movements of the main and the auxiliary lift, we can position the fork faster in front of the rack with the new MX-X and after retrieval move the pallet faster with a smooth, flowing movement”, the experienced logistics service provider underlines.

More stability by the new design of the turret head mechanism

The mechanism of the turret head was redesigned and made more compact with the help of the new hydraulic drive. The side shift is smoother and the stability of the lift as a whole has been increased. This makes the MX-X a much more stable and silent truck in the narrow aisles. And the chain to swivel the fork has been made redundant. This saves service costs.

Easy control, intuitive key assignment

The design, controls and the display of the control panel have been revised. The keys can be assigned individual functions using the available options such as light or the favourites. All the important information, like the load weight and the lift height, the steering angle or the Optispeed 4.0 functions are now shown on the top level of the colour display and are available without switching the view. To make order picking easier, the control panel was made flatter and less deep.

More safety thanks to revised rear view mirrors

The drivers can quickly adjust the rear view mirrors without using tools. The mounting of the mirrors on the truck have also been improved.

Modular planning of the truck allows on-site truck configuration

With the new planning software from STILL, it is now possible to adjust, test and optimise the new MX-X truck using 20 different types. Jochen Mühleisen, system salesman at STILL Stuttgart, says: “The tool to configure the trucks is also available on our mobile computers. This allows us to set all the parameters on-site. The planning software then calculates the best possible design of the MX-X.”

Summary

With the triplex standard, the trucks of the new MX-X truck series from STILL reach heights of 18 metres. This increases the utilisation of warehouse space. Thanks to the stabilisation of the load and the simultaneous movement of the main and auxiliary lift, the time needed for storage and retrieval is shorter. In combination with the optimisation of cabin ergonomics and the reduced vibrations when picking parts, the turnover performance is substantially increased.