Compact storage systems for maximum efficiency

Automated storage and retrieval with 4-way pallet shuttles – space-saving, flexible, powerful

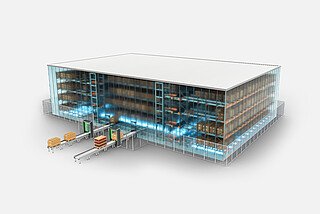

Efficient storage in the smallest space: The STILL iGo cube is a fully automated compact storage system that combines maximum space utilization with high scalability and easy integration. Whether as a logistics or production buffer, cross-dock, or main warehouse – iGo cube adapts flexibly to your requirements and increases the efficiency of your internal logistics. Thanks to standardized modules, the system is quick to implement and seamlessly integrates into existing warehouse structures – regardless of floor conditions or ceiling height.

- Quick and easy implementation: Thanks to standardized modules, the system is quickly operational and adapts to existing warehouse layouts.

- Maximum storage capacity in minimal space: The system makes optimal use of your available warehouse space – with high-density storage and flexible integration into existing structures.

- Scalable for growing requirements: Storage capacity and performance can be adjusted at any time – from small warehouses to high-performance solutions.

- Automated, reliable warehouse logistics: Maximum security and minimal downtime thanks to intelligent control, redundancy, and seamless tracking of all processes.

- Efficient handling of different load carriers: iGo cube stores various pallet types and goods flexibly – even within mixed channels.

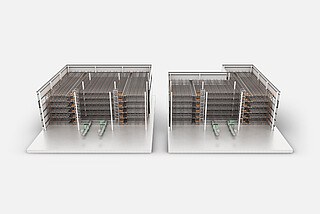

The iGo cube compact storage system is modular. Its components can be flexibly combined to meet different storage capacity and performance requirements.

- Warehouse Control System (WCS)

The WCS centrally controls and manages the 4-way pallet shuttle system. It coordinates transport orders, manages storage locations, and optimizes warehouse processes. - Conveyor pre-zone

Incoming pallets are manually transferred or delivered by automated guided vehicles (AGVs) such as the STILL EXV iGo. Automatic contour and weight checks ensure that only compliant load carriers are stored. - Pallet and shuttle lift

Each pallet is automatically assigned a storage location based on defined criteria such as article number or batch. Lifts transport pallets to the correct rack level, while shuttles can change levels via the lift. - Main aisle

Each level has main aisles connecting the lifts with the storage lanes, ensuring efficient pallet transport. - Storage lanes

The storage lanes provide compact and systematic storage of pallets, which are retrieved automatically when needed. - 4-way pallet shuttle

The shuttles transport pallets within the storage lanes and retrieve them when requested. The number of shuttles can be flexibly adjusted depending on the required performance level.

Your warehouse grows – and iGo cube grows with it. More capacity, maximum efficiency, complete control: The fully automated compact storage system optimizes your storage space today – and adapts flexibly to future demands.

Optimum space utilization

The iGo cube system can be seamlessly integrated into existing warehouse layouts, maximizing available storage space.

Suitable for various working environments

The system operates reliably in ambient, refrigerated, and deep-freeze warehouses down to -28 °C.

Flexible load carrier handling

iGo cube enables the storage of different load carriers such as EPAL and industrial pallets – even with varying dimensions, goods, or weights within the same channel. The system supports load weights of up to 1,500 kg per pallet.

Autonomous loading

The shuttles automatically approach the loading points when required.

4-way pallet shuttle

The shuttle moves in four directions and adapts flexibly to your warehouse layout. Every transport movement and load can be tracked in real time. Additional shuttles can be added at any time to increase system performance.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday

What happens after sending?

1. You will receive an automatic confirmation by email

2. Your request will be checked by our team of experts

3. You will receive a personalised response within 24 hours

Use the contact form

Write to us – we will get back to you

Intralogistics automation with STILL iGo

The iGo cube is part of STILL’s automation solutions and can be seamlessly integrated into automated warehouse processes. Discover the possibilities of combining the compact storage system with automated guided vehicles (AGVs), autonomous mobile robots (AMRs), or autonomous horizontal order pickers.