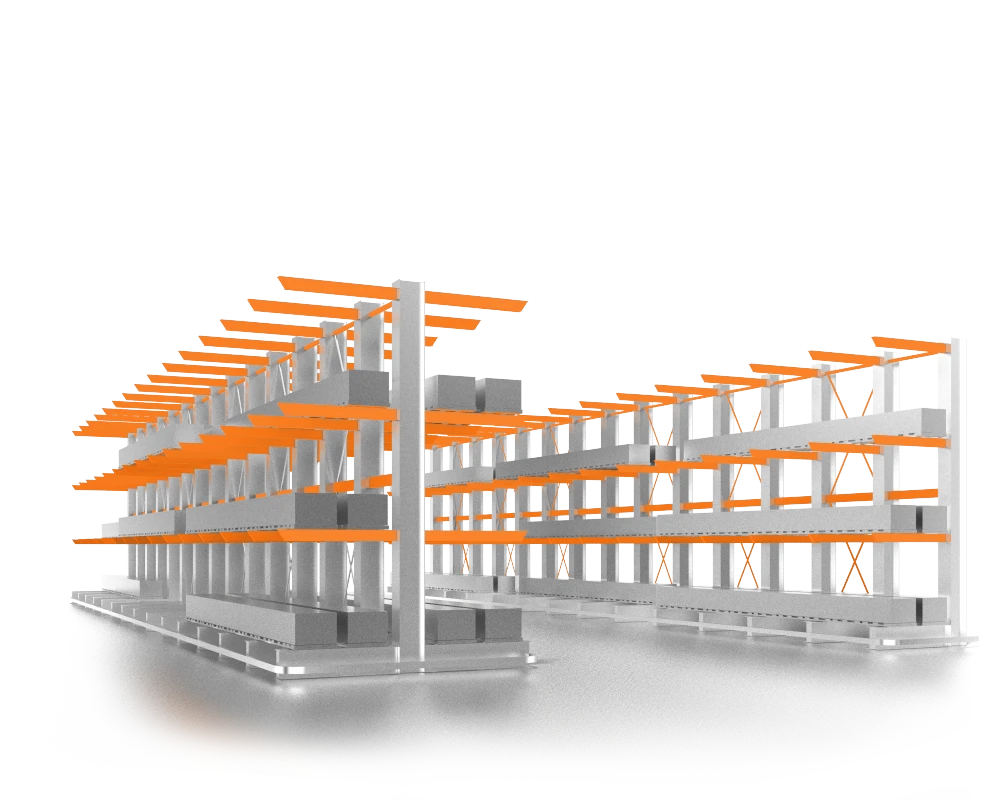

Racking Systems Cantilever racking

Made precisely to your requirements

- Tidy and clearly arranged storage of bulky and long goods

- Optimum use of storage space and building height

- Optimum and direct access to goods

- Design for outdoor use with roof and wall panelling available

- Suitable for light loads and very heavy loads

Do you want to primarily store long products and bulky goods, e.g. pipes, plates, boards and rods? If so, it is essential that you have a good look at STILL's cantilever racks. Thanks to its design, this type of rack offers the possibility of neatly storing goods with a variety of dimensions.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday

What happens after sending?

1. You will receive an automatic confirmation by email

2. Your request will be checked by our team of experts

3. You will receive a personalised response within 24 hours

Use the contact form

Write to us – we will get back to you

The cantilever rack consists of rack stands and cantilevers. The rack stand consists of the stand itself, the stand feet, longitudinal connectors and at least one diagonal brace. The cantilevers are bolted to the rack stand.

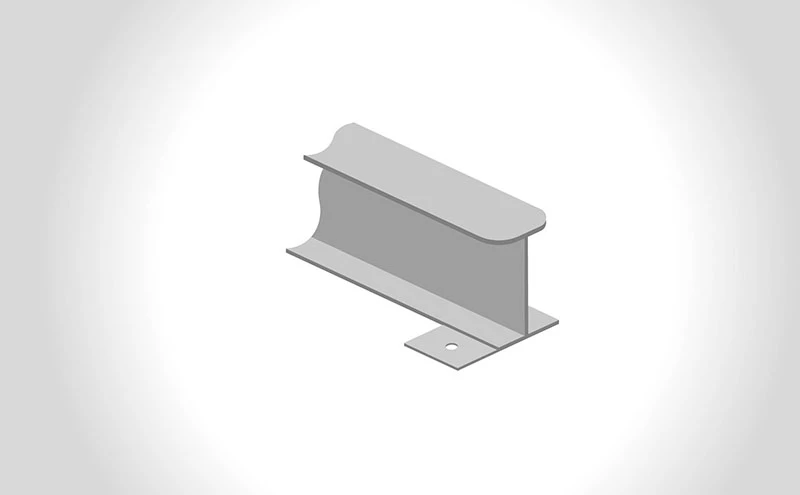

Rack stand with stand foot

The main component of the cantilever rack is the single- or two-sided rack stand with one stand foot. It is anchored to the floor. The size and design are dependent on the required load and the static requirements. The hole perforations for mounting the cantilevers extend to the top storage level. The standard height spacing is 100 mm and serves the purpose of easy adjustment of the shelf height. Other distances are possible on request.

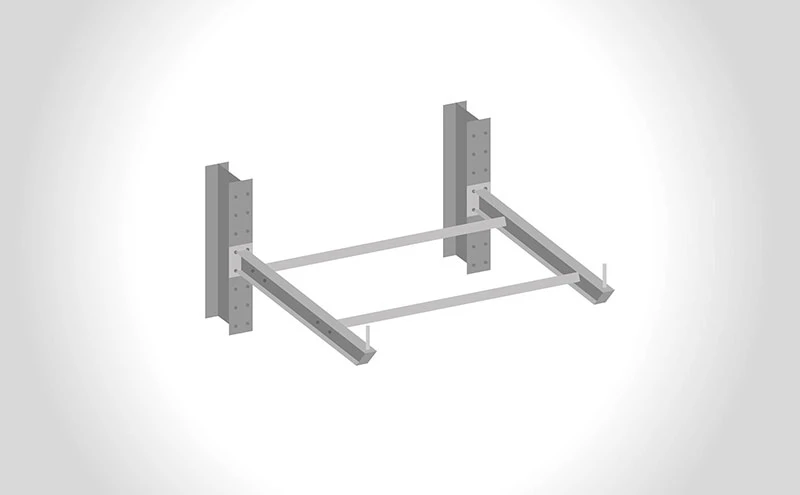

Cantilevers

The cantilevers are bolted to the rack stand. The construction of the cantilevers is dependent on the load. The bigger the profile, the greater the possible load-bearing capacity.

Diagonal brace

At least one diagonal brace with adjustable turnbuckles is required for each rack. For normal loads this bracing is sufficient on every fifth or sixth bay.

Longitudinal connectors

The longitudinal connectors act as spacers between the stands. The length of the longitudinal connectors is governed by the type of product stored.

Rounding of the feet

The rounding serves the purpose of protecting personnel (the shins, for example, are protected by this) and vehicle tyres.

Roll-off prevention devices

Roll-off prevention devices are important for keeping round products securely on the cantilevers. The roll-off prevention devices can be supplied in different versions and heights.

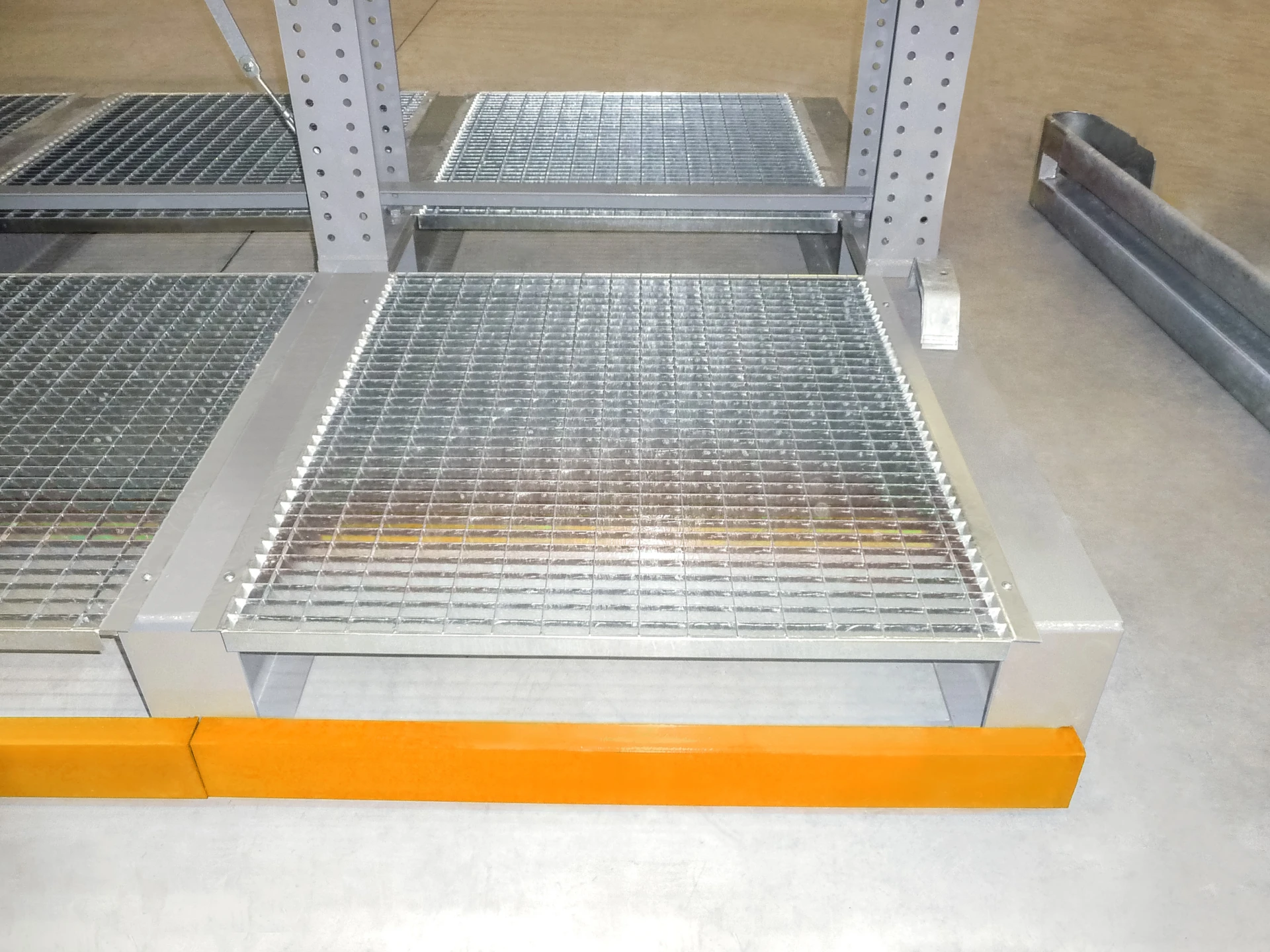

Bridging arms

Cantilever racks serve the purpose of storing long products. Bridging arms are elements that are screwed between the cantilevers, enabling the storage of pallets.

Shelf cover

To make utilisation of the rack more flexible, we offer you various versions of the shelf cover. The covers are either laid only on the cantilevers or they are laid on bridging arms mounted between the cantilevers. Particle boards, gratings or grid floors are possible covers.

Storage labelling

Two important aspects need to be considered to provide customer-oriented labelling: Position of labels and shelf position numbering.

Position of labels

The labels on the rack are not always easily visible. To ensure good visibility, we help with rack-specific label holders.

Shelf position numbering

In particular if you store rods, pipes, plates etc. in your warehouse, it is important to maintain an overview. We offer you correct numbering to meet your individual requirements.

Entry guards and guide rail

If required, the guide rail provides industrial trucks with lateral guidance. The entry guard can only be used in combination with the guide rail to allow the truck to smoothly enter the aisle.

Collision guard

The collision guard is available L-shaped or U-shaped to protect two or three sides. It is mounted to the outer rack support of each aisle. (acc. to the requirements of the German BGR 234, the height is at least 300 mm)

When talking about cantilever racks, one often refers to the axial dimension. The axial dimension is measured centre to centre of two cantilevers. The oversize of long material reaching over the last cantilever is limited to half of the axial length. At a given axial dimension of 1000 mm, this means the maximum allowed oversize is 500 mm.

A warehouse planned for efficiency guarantees high economic feasibility. Benefit from the professional consultation with our STILL experts right from the start of warehouse planning. Before you make a buying decision, we assist you in every aspect – from checking your warehouse design to discussing the planned workflows. There are many reasons why you should decide for STILL when buying a cantilever rack:

- Many years of expertise: Close to our customers for more than 95 years.

- Partnership that you can rely on.

- Holistic premium concept – from consultation to service.

- Always close to you: 14 branches, 37 rental branches & 800 service technicians in Germany alone.

- A trained installation team ensures proper assembly of your cantilever rack.