BSH Hausgeräte Service Nauen GmbH. Over three million large appliances – that’s efficient fleet management!

Sector: Electrical

Company: Part of the Bosch group, largest manufacturer of household appliances in Europe; 61,000 employees in 42 plants worldwide.

Challenge: Fleet management for a distribution centre with over 140 industrial trucks – up to 20,000 large appliances are delivered each day.

The solution: Online portal with access to all relevant truck and fleet information.

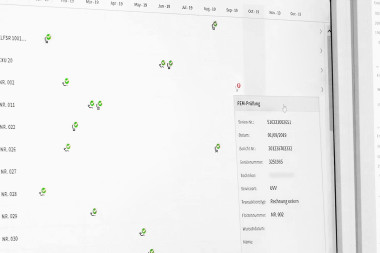

STILL products: STILL neXXt fleet: clear and immediate display of all data, automatic notifications, e.g. cost values and appointments (e.g. FEM check) – access via mobile device.

At BSH Hausgeräte Service Nauen GmbH, an innovative fleet management system helps ensure a yearly goods turnover of over three million large appliances for households and kitchens. In the distribution centre, there are over 140 industrial trucks in use; these are gradually being fitted with STILL’s neXXt fleet and FleetManager 4.x fleet management software in a transparent and flexible manner. Whether it’s energy consumption, operating hours or information on the suitability of specific types of truck for certain applications, the STILL neXXt fleet online portal provides valuable data for analysing trucks on an ongoing basis. When it comes to availability, user-friendliness and visualisation, this progressive fleet optimiser is setting new standards.

Powerful fleet management system helps ensure up to 20,000 large appliances are delivered on time each day

At the BSH supply centre in Nauen, large appliances such as dishwashers, freezers and refrigerators from other BSH production facilities are brought together with other washing units that are produced at the Nauen plant and distributed to more than 20 transfer points across Germany. Lothar Kusche, Head of Technical Services and Transport: “In the last ten years, the number of industrial trucks has continued to rise due to the huge increase in goods turnover. Almost 25 years ago, we started with ten STILL forklift trucks. Now we operate a fleet with over 140 industrial trucks, which we use to load up to 20,000 large appliances a day.”

Fleet optimiser STILL neXXt fleet sets new standards

The relevant information for fleet management is clearly displayed in the STILL neXXt fleet online portal. This consists of a variety of web applications, web apps for short, which can be accessed easily and conveniently from anywhere. In neXXt fleet, commercial and technical data from STILL’s SAP host system is combined with the truck’s operating data in one database, enabling the trucks to be analysed quickly and their usage to be optimised. Lothar Kusche adds: “neXXt fleet allows us to effectively monitor expenses for repairs and truck damage as well as service and maintenance. Data is transferred quickly and error-free and all data for each truck can be clearly displayed straight away. Automatic notifications on certain cost values or appointments, such as FEM checks, are clearly displayed together with test reports.” 2 — STILL I BSH In this way, the necessary data for a truck is immediately compiled and individually selected for the respective application of the appropriate truck. In the web portal, there is also the option of dividing up the trucks into groups, such as incoming and outgoing goods. This results in optimal utilisation and improved control of the trucks, summarises Kusche. Phillipp Schmidt, Head of Product Management Applications & Services at STILL, adds: “Our fleet optimiser neXXt fleet provides everything required for the intelligent capture of operating data, as well as analysing and preparing them. This makes it easier to implement processes in logistics in an easier, faster and more cost-efficient manner.”

STILL neXXt: Web portal for all services

STILL’s product portfolio has included software solutions for many years. The online portal neXXt fleet is an application of the company’s internal digital ecosystem STILL neXXt. The portal enables users to control a variety of applications with just one login for the first time, even from mobile devices.

Reduction in accidental damage

Thanks to the access authorisation for the trucks, all operating data is recorded transparently in FleetManager 4.x and transferred to neXXt fleet for evaluation. As a result of this high level of transparency in fleet management, a reduction in the number of accidents was recorded in the BSH logistics centre. This is because heavy impacts on the truck are reliably detected using a shock sensor.

Summary

At the BSH supply centre in Nauen, the fleet optimiser STILL neXXt fleet provides all relevant data relating to the trucks, stores it transparently in a central database, and enables precise analysis in order to optimise fleet management. This provides a greater overview and improved monitoring of the investment, maintenance and repair costs.