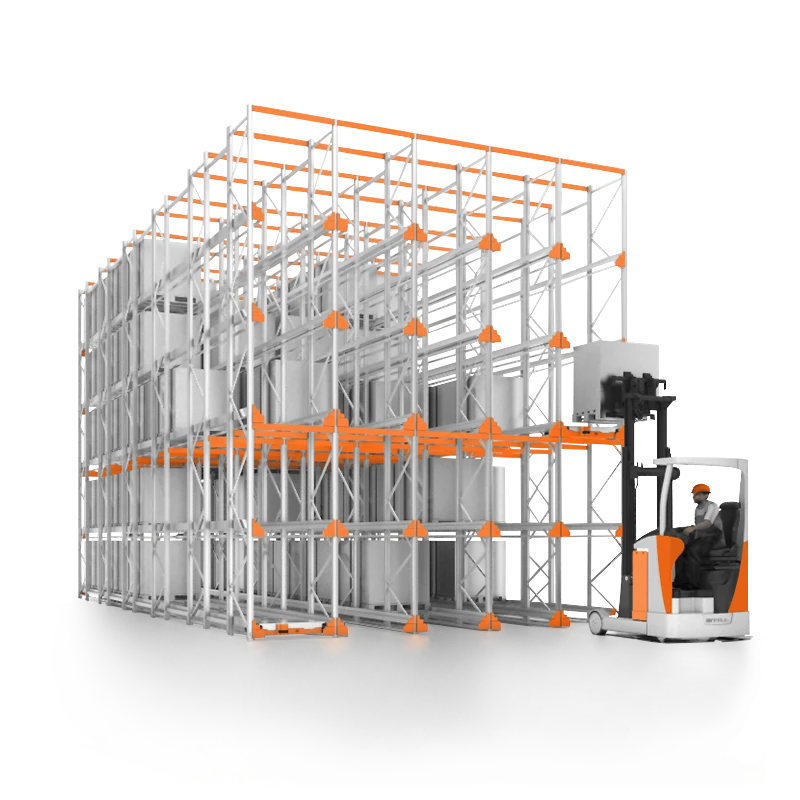

Racking Systems STILL pallet shuttle rack

Automatic storage made easy

- Maximum use of storage volume

- Time-saving due to simultaneous use of shuttles and industrial trucks and semi-automatic storage and retrieval

- Higher flexibility compared to conventional compact storage systems such as drive-in racks: Several rack levels can be loaded.

- Higher turnover performance: Semi-automatic storage and retrieval: LiFo (Last-in-First-out) and FiFo (First-in-First-out) possible

- Careful transport of loads

You expect maximum warehouse and space utilisation with high handling speeds from your warehouse? Then you should take a close look at the shuttle racks from STILL. To enable you to make best use of your space, we offer you a perfect combination of a high-density STILL pallet shuttle rack and our smart pallet shuttle.

The high-density shuttle storage system allows semi-automatic storage and retrieval of load carriers. A pallet shuttle moves the load down the channel and stores the pallet in the rack. The system allows independent loading of several channels.

Remember: Time and storage space are valuable. Optimise the utilisation of existing space with a shuttle storage system, even if you need to store a variety of products.

Truck and shuttle work together hand in hand. The principle is as easy as it is efficient. The truck drops the load at the entry of the channel. The load is then picked up by the shuttle and is automatically moved to the end of the channel or the next available storage space. The pallets are carefully placed on the support rails and the shuttle returns to the entrance of the channel to pick up the next pallet. Convenient: The shuttle automatically detects the end of a channel.

With a pallet shuttle you save considerable time and increase safety in the warehouse: The truck does not have to drive inside the rack and the transported goods are handled very carefully compared to block storage. By standard, the STILL pallet shuttles are equipped with a mobile pedestrian protection system to guarantee safe operation.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday

What happens after sending?

1. You will receive an automatic confirmation by email

2. Your request will be checked by our team of experts

3. You will receive a personalised response within 24 hours

Use the contact form

Write to us – we will get back to you

The STILL pallet shuttle rack is virtually identical with a drive-in rack. With the difference that the trucks do not move into the rack and that each level is individually accessible. Pallets are stored directly at the rack face and moved inside the rack with a pallet shuttle.

Rack support

The rack supports are elementary components of the rack and are made of special steel profiles with different thicknesses depending on the expected load weight inside the channel. Two supports are bolted to the profiles to form a support. The rack supports are securely bolted to the floor.

Longitudinal beam

The columns of the racks are connected lengthwise by longitudinal beams to add stability to the rack. There are no longitudinal beams on the storage and retrieval ends to ensure smooth transfer of pallets in the channel.

Support rail

The support rails in the shuttle rack are attached with mounts on the support and fulfil two functions: they support the pallets and the shuttle beneath the pallets also moves along the rail. In each channel, the mounting height can be individually varied in steps of 50 mm. As the rails are simply hooked into the supports for each channel, it is very easy to modify the system if required.

Wheel stop

The wheel stop in front of the rack helps stopping the feeding truck at a defined distance in front of the rack. This prevents damages from the rack.

Pallet shuttle

The task of the shuttle is to semi-automatically store and retrieve the pallets from the rack. The dimensions of the used shuttle must correspond to the dimensions of the moved load. We provide you with solutions for Euro-pallets, industrial pallets and selected types of chemistry pallets. The transport speed of the shuttles is 0,9 to 1,1 m/s. The shuttles are not only agile, but also extremely strong. With a maximum load capacity of 1 500 kg they also store heavy load carriers fast and safe. Talking about safety: to ensure a safe operation, the pallet must not bend by more than 10 cm at its centre. High safety levels are guaranteed by the personal protection scanner which is fitted to every shuttle by standard.

Pallet centring

The pallet centring equipment allows to place the pallet accurately into the rack. With the pallet centring equipment it is easy to place the pallet precisely in the centre between the rails.

Recovery platform

The recovery platform is used to safely recover a shuttle or load from the rack. The recovery platform is operated manually. It allows recovery teams to move down the channel to approach a broken-down shuttle. The broken-down shuttle can be towed out of the channel with a hook.

Side reach guard

Side reach guards are mounted on the side of the rack to prevent access over the side during operation. This prevents accidents.

A warehouse planned for efficiency guarantees high economic feasibility. Benefit from the professional consultation with our STILL experts right from the start of warehouse planning. Before you make a buying decision, we assist you in every aspect – from checking your warehouse design to discussing the planned workflows. There are many reasons why you should decide for STILL when buying a pallet shuttle rack:

- Many years of expertise: Close to our customers for more than 95 years.

- Partnership that you can rely on.

- Holistic premium concept – from consultation to service.

- Always close to you: 14 branches, 37 rental branches & 800 service technicians in Germany alone.

- A trained installation team ensures proper assembly of your pallet shuttle rack.

Downloads

The document provided for download is the updated version of the operating instructions for the standard truck. It does not include descriptions of customer options (Customer Option). For a concrete truck, please request the respective specific manual according to the serial number and the year of production from the STILL spare parts service.