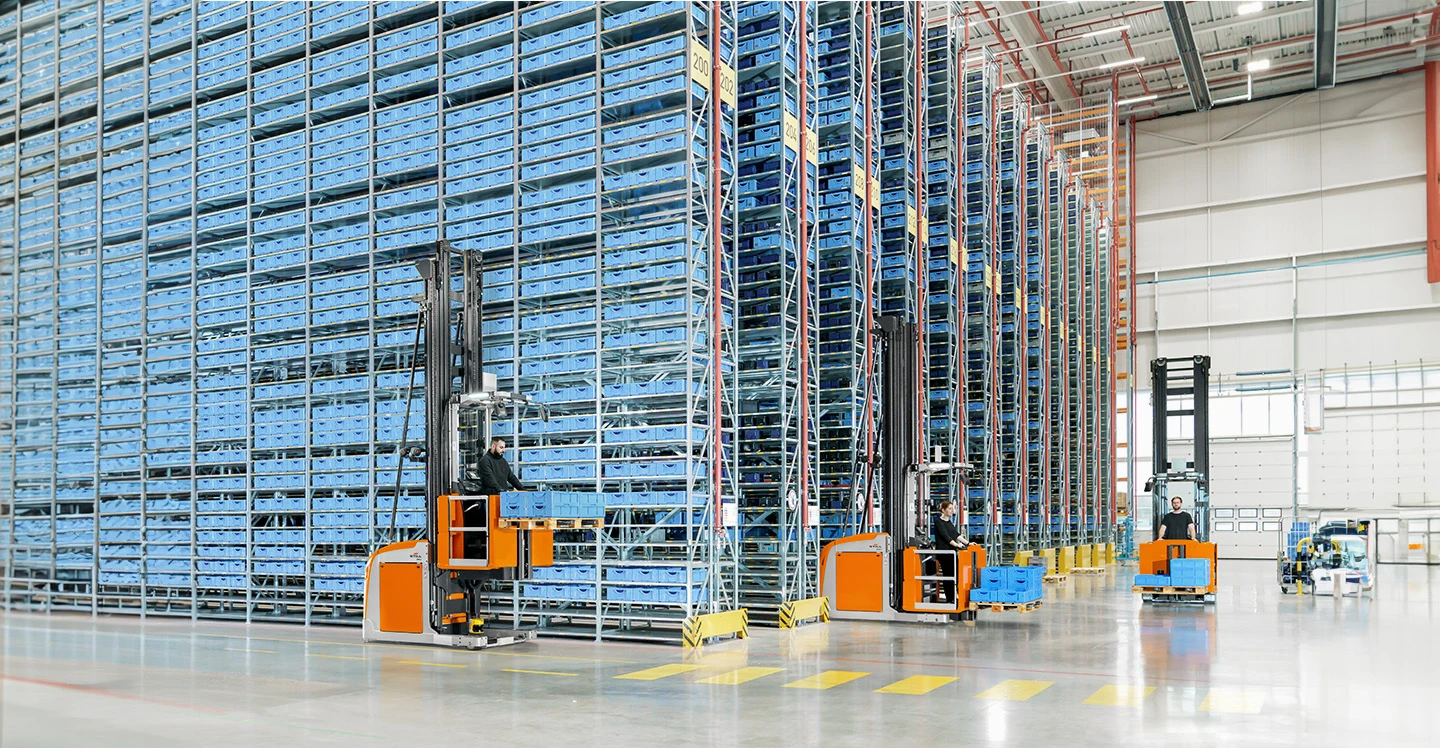

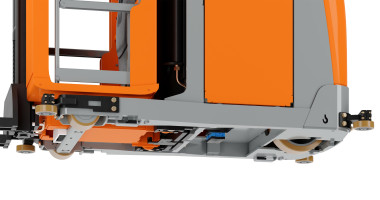

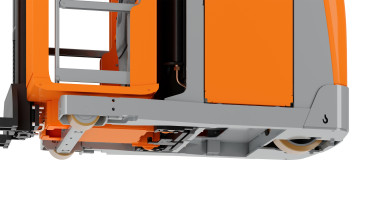

Vertical Order Picker PXV up to 1.200 kg

The new dimension in order picking

- Load capacity 1200 kg

- Grip height 14500 mm

- Speed 13 km/h

It is the king of order picking and impresses with its exceptional goods handling and maximum reach heights, as well as offering a whole new level of safety and ergonomics. Whether put to use in wide or narrow-aisle warehouses, no other order picker uses space and time as cleverly as the PXV vertical order picker. With an order picking height of 14.5 metres, the ‘large’ variant – which has a load capacity of 1,200 kg – can reach even the highest shelves. Its little brother meanwhile can work at reach heights of up to 7.8 metres with a load capacity of 1,000 kg. In both versions, smooth mast transition journeys not only ensure comfortable working but also impressive goods handling.

The PXV sets new standards when it comes to user friendliness and ergonomics, too. The operator is supported by intelligent assistance systems, such as the STILL OptiSpeed system which ensures the highest possible speed without jeopardising driving safety. It also offers an excellent field of vision in the load and drive direction, plus a spacious, shock-absorbing operator's cab with tilting barriers for easy access to goods. Additional assistance systems for even greater safety and efficiency plus numerous equipment variants can also be selected individually and make the PXV the perfect, tailor-made companion for every warehouse. It's the new dimension in order picking.

The "Simply Efficent" factors: Performance attributes as a measure of economic efficiency

Simply easy

Particularly sensitive operation and continuous control of lifting speed

thanks to the latest proportional valve technology

Intuitive control

through the steering wheel or steering knob makes it easy for the operator to use all functions, customised to their needs

Optimum user comfort

provided by the spacious shock-protected stand-on platform with integrated presence switch

Quick and easy charging at any time

thanks to optional opportunity charging in lithium-ion variants

Simply powerful

Reliable availability

with powerful, low-maintenance AC drives for driving and lifting

Efficient and powerful performance

for every customer requirement thanks to individually configurable driving and lifting speeds

Unrivalled space utilisation

with a reach height of up to 14.5 metres

Fast lifiting and lowering speed

thanks to mast without free lift and without mast transition journeys

Optimum handling performance

thanks to smart OptiSpeed assistance system in a range of customised versions

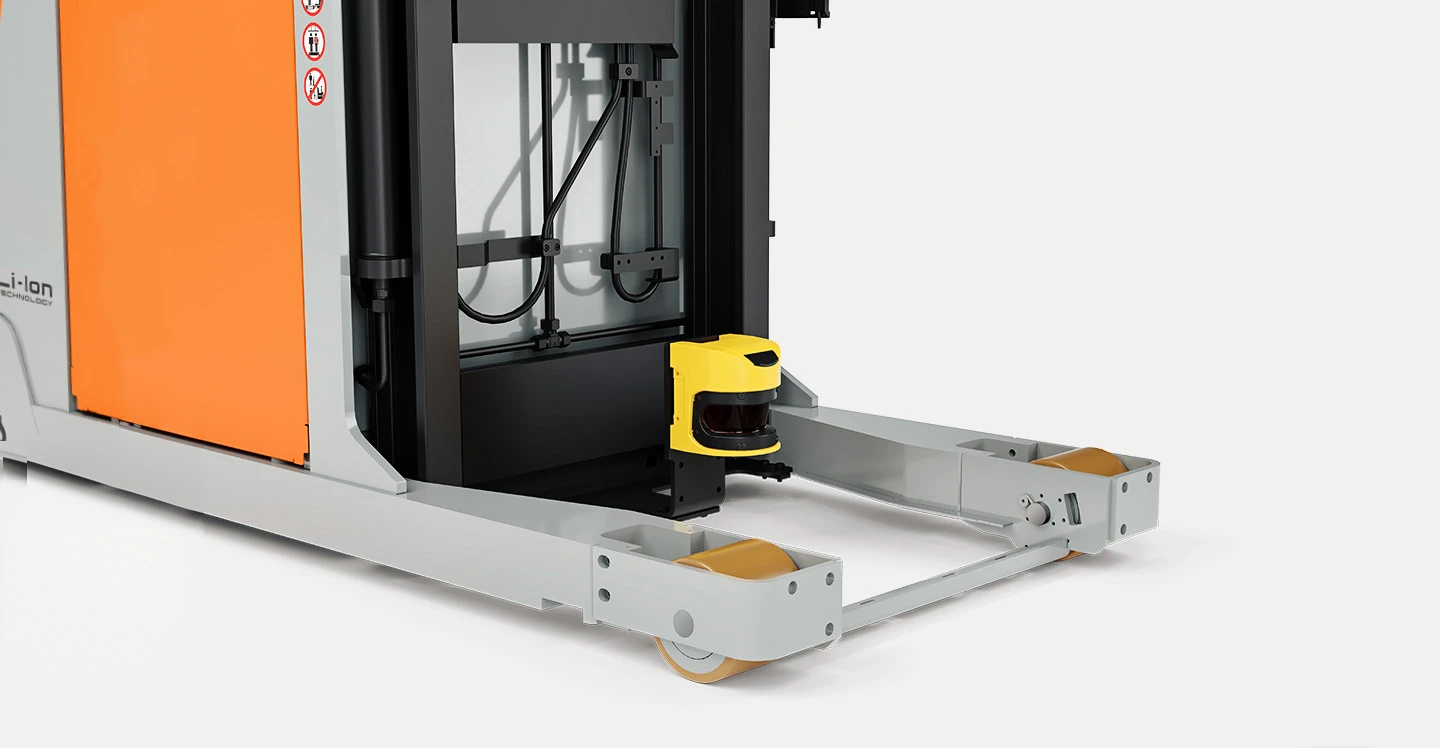

Simply safe

Operating safety guaranteed

with innovative iGo pilot safety aisle safety assistant

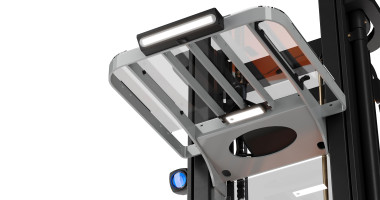

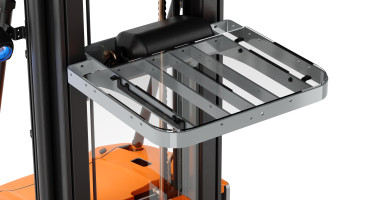

Optional tilting barriers

allow reduced distance between truck and rack – for quick, safe and ergonomic order picking

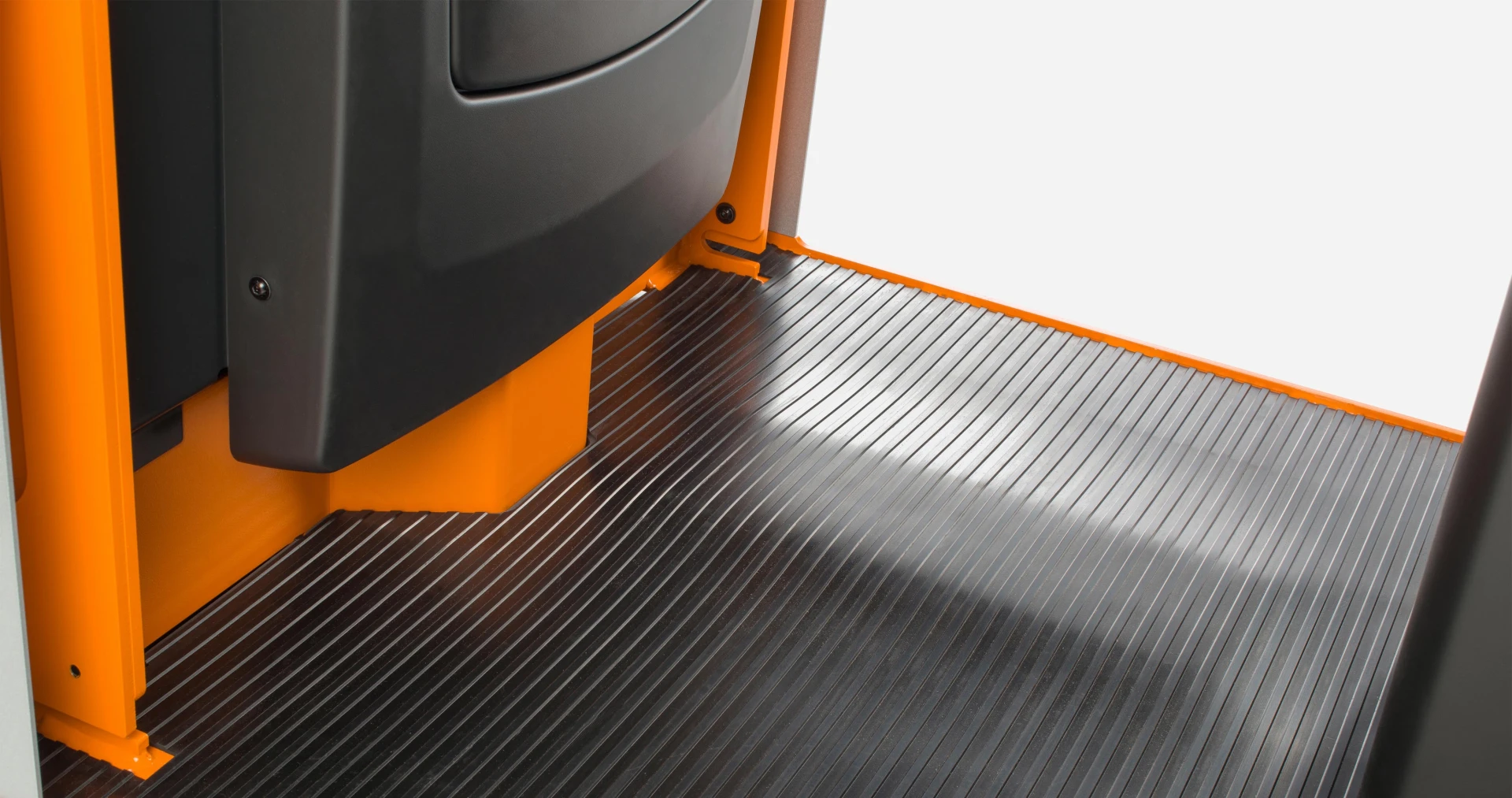

Safe, comfortable and healthy operator's cab

with optional knee and support cushions

Optimum truck and operation safety

with electronic monitoring of battery locking

Simply flexible

Individually configurable for a wide range of uses

thanks to modular truck concept

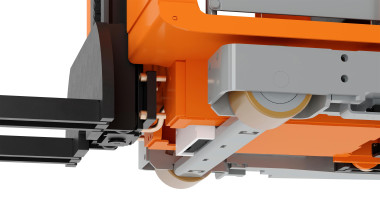

Accessible pallet

allows the operator to enter the pallet to pick bulky and heavy goods

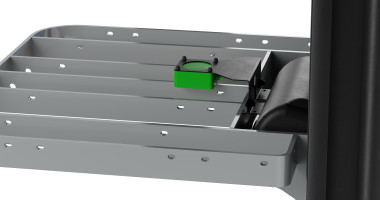

Flexible operator's cab design

using a mounting bar system for simple integration of tools (optional)

Simply connected

Maximum handling

with intelligent STILL iGo pilot navigation assistance system and semi-automated bay approach

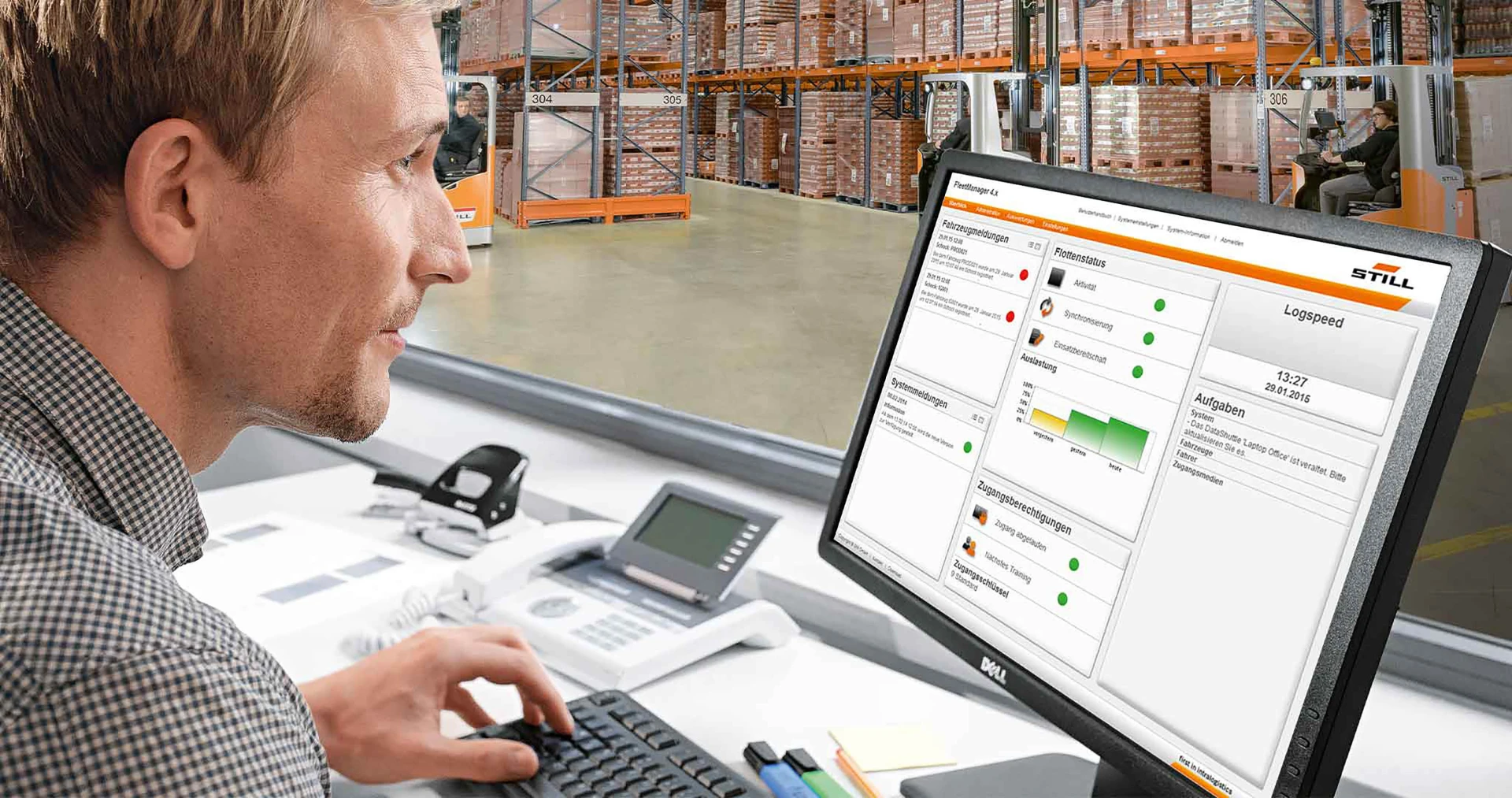

Simple connection to warehouse management system

for optimum control of goods flow with STILL iGo pilot interface

Optimum truck safety, access protection and damage minimisation

with STILL Smart Portal

STILL Li-Ion Technology inside

The perfectly harmonised power system for reducing operating costs and increased truck availability.

More about STILL Li-Ion TechnologyForklift driver assistance systems

Sharpening all senses: we can support you with our wide range of smart driver assistance systems and functions which will make your day-to-day work significantly easier. You will be able to drive in a safer, more comfortable, efficient and fatigue-free manner – in every driving situation.

The visual warning system for fewer accidents

The blue warning light, STILL SafetyLight 4plus, significantly increases work safety in areas which are confusing or full of bends. The blue light spots are projected approx. 5 m in front of and behind the truck and warn people about the approaching truck to prevent impending collisions.

Learn moreSafety in the warehouse is increased thanks to an acoustic signal during reversing. Colleagues are therefore able to notice the forklift truck even if they have their back to it.

Learn moreWith the mobile personal protection system from STILL, you are on the safe side when it comes to protecting people in narrow aisles. Sensitive safety scanners on the drive and load sides of the VNA truck monitor the route and reliably detect people in the aisle. Thanks to the latest scanner technology, the STILL PPS meets all legal requirements for occupational health and safety and workplace regulations - in a lean and efficient way.

Learn moreThe predictive braking system reliably detects static obstacles on the route in good time in aisles or warning fields at a distance of up to 8 meters and triggers the truck to react accordingly. Depending on the warning zone and individual configuration, this can be an acoustic signal, a speed reduction or even stopping the vehicle. The system can be easily integrated into existing or new forklift truck solutions and flexibly configured according to individual customer requirements - effectively reducing collisions and impact damage inside* and outside the narrow aisle.

*not in accordance with DIN 15185-2

If desired, you can limit the usage of your forklift truck to specific persons or groups of persons via access authorisation. Select whether the release of the truck should be carried out using a key switch or via a digicode system with ten configurable access codes (or PINs).

Learn more

Digicode systems (PIN) are an easy way to prevent unauthorised use of the truck. The truck can be started up quickly and easily, simply by entering the PIN code. This allows the user to limit access authorisation to specific individuals or groups. It is possible to configure up to ten PIN codes.

More information

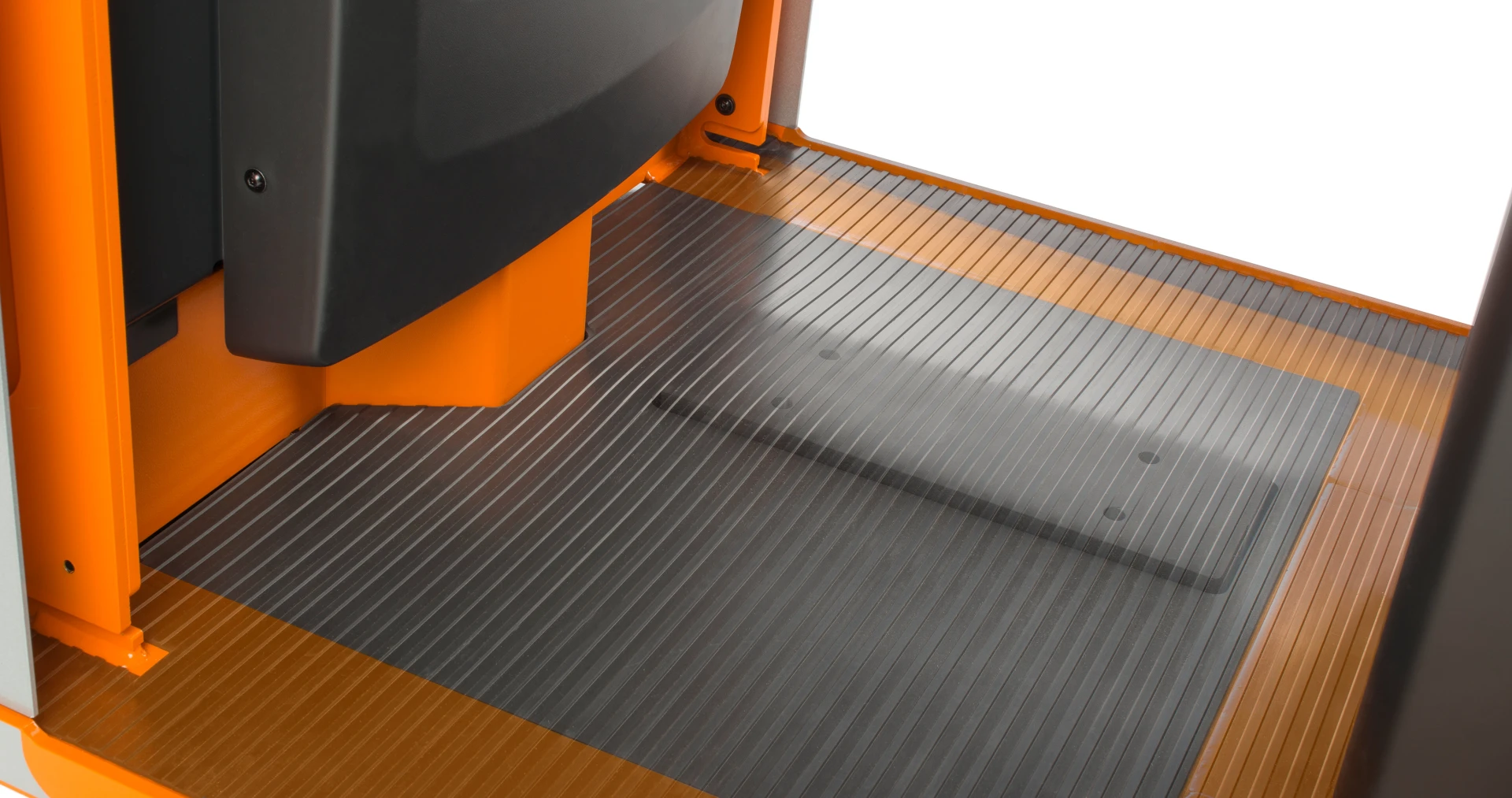

Like driving on feathers:

the shock-protected cab floor relieves pressure from the employee and a large foot pedal allows for a variable and comfortable stationary position.

Learn moreAutomatic speed adjustment for curves

The speed limiter controlled by steering angle reduces possible damage to goods by adapting to an appropriate cornering speed. This assistance function is available for various forklift trucks and warehouse technology devices, and regulates the driving speed automatically according to the steering angle. In other words, the driver doesn’t need to worry about speed when cornering. The truck automatically decelerates precisely as much as necessary for the operator to drive as safely but as quickly as possible.

Learn moreMaximum handling capacity: STILL OptiSpeed

Comprehensive hardware and software assistance systems which optimise the movements of the equipment regardless of the load. This significantly increases your handling capacity.

The system combines the advantages of OptiSpeed 3.1 with a weight sensor: in addition to the visual and acoustic signals when specific limit values are reached, a travel and lift stop is triggered when the permissible load weight is exceeded.

In addition, it calculates ideal transport movements and optimises them based on the lifting height and load.

This enables higher speeds on empty runs or when loading and picking.

|

Model

|

Maximum capacity (kg)

|

Maximum reach height (mm)

|

Travel speed (km/h)

|

Battery voltage (V)

|

|---|---|---|---|---|

| PXV/Li-Ion | 1200 | 14500 | 13 | 48 |

Downloads

The document provided for download is the updated version of the operating instructions for the standard truck. It does not include descriptions of customer options (Customer Option). For a concrete truck, please request the respective specific manual according to the serial number and the year of production from the STILL spare parts service.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday

What happens after sending?

1. You will receive an automatic confirmation by email

2. Your request will be checked by our team of experts

3. You will receive a personalised response within 24 hours

Use the contact form

Write to us – we will get back to you