Racking Systems Push back and pallet flow racking

Economic solution for optimised goods handling

- Optimum flow of materials for FiFo

- Time-saving retrieval due to automatic pallet movement

- Optimum utilisation of warehouse space - compared to conventional racks, warehouse utilisation can be increased by up to 60%

- Optimised material flow due to separation of storage and retrieval and shorter transport distances

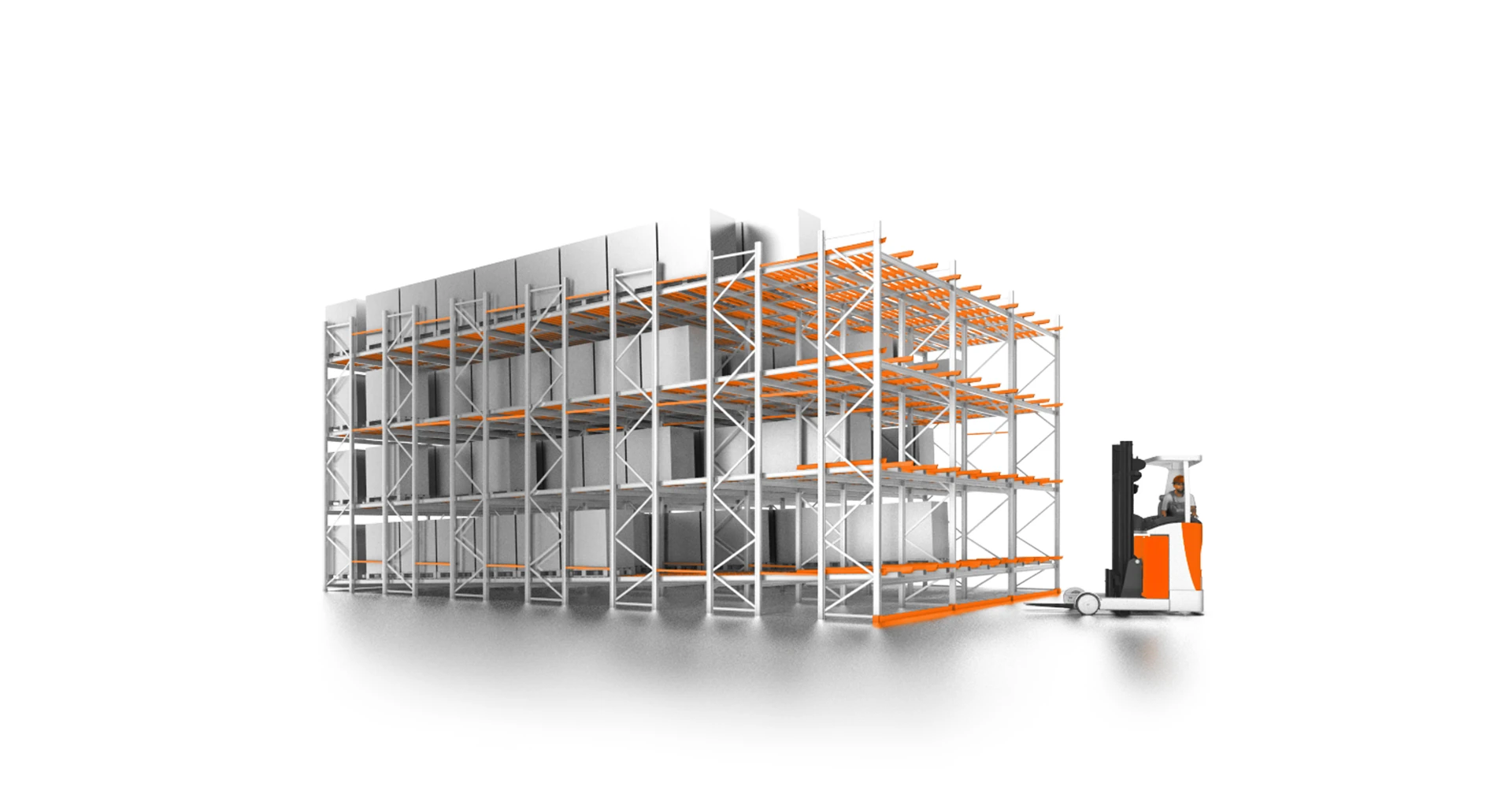

Do you need to store single types of goods and materials with a high turnover rate? Then take a look at the STILL pallet flow racks. Pallet flow racks are dynamic rack systems following the FiFo principle (First in - First out). They ensure high storage capacity and excellent utilisation of space. This is made possible by the goods automatically moving towards the rack face.

In pallet flow racks, the weight moves the pallets automatically from the storage to the retrieval position travelling on an inclined roller track. In this way, according to the FiFo principle, the pallet, which was stored first, is ready for retrieval at any time and can be accessed directly. The pallet flow rack is ideally suited for dispatch areas or tour preparation, for example, or can function as a buffer between two work stations or as a picking warehouse for full pallets.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday

What happens after sending?

1. You will receive an automatic confirmation by email

2. Your request will be checked by our team of experts

3. You will receive a personalised response within 24 hours

Use the contact form

Write to us – we will get back to you

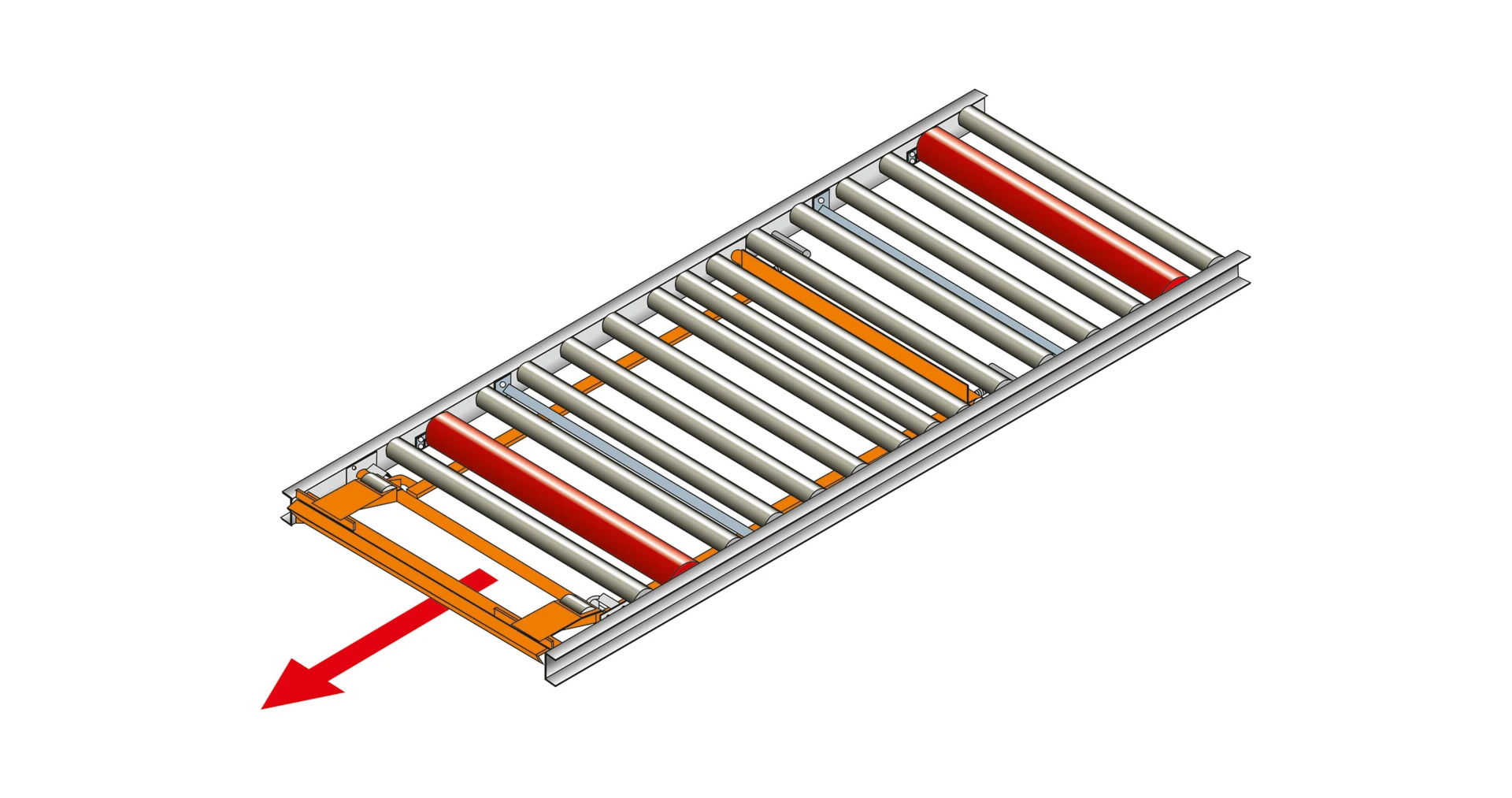

Push back racks are dynamic rack systems that follow the Last-in First-out (LiFo) principle.

The products are stored and retrieved from one side only. Because the tracks are inclined, the remaining products automatically move towards the storage and retrieval end when a pallet is retrieved.

- Ideal buffer storage due to LiFo principle

- Efficient storage and retrieval thanks to automatic movement of the pallets down the channel

- Optimum use of storage volume

- Space-saving: A single aisle for trucks is sufficient

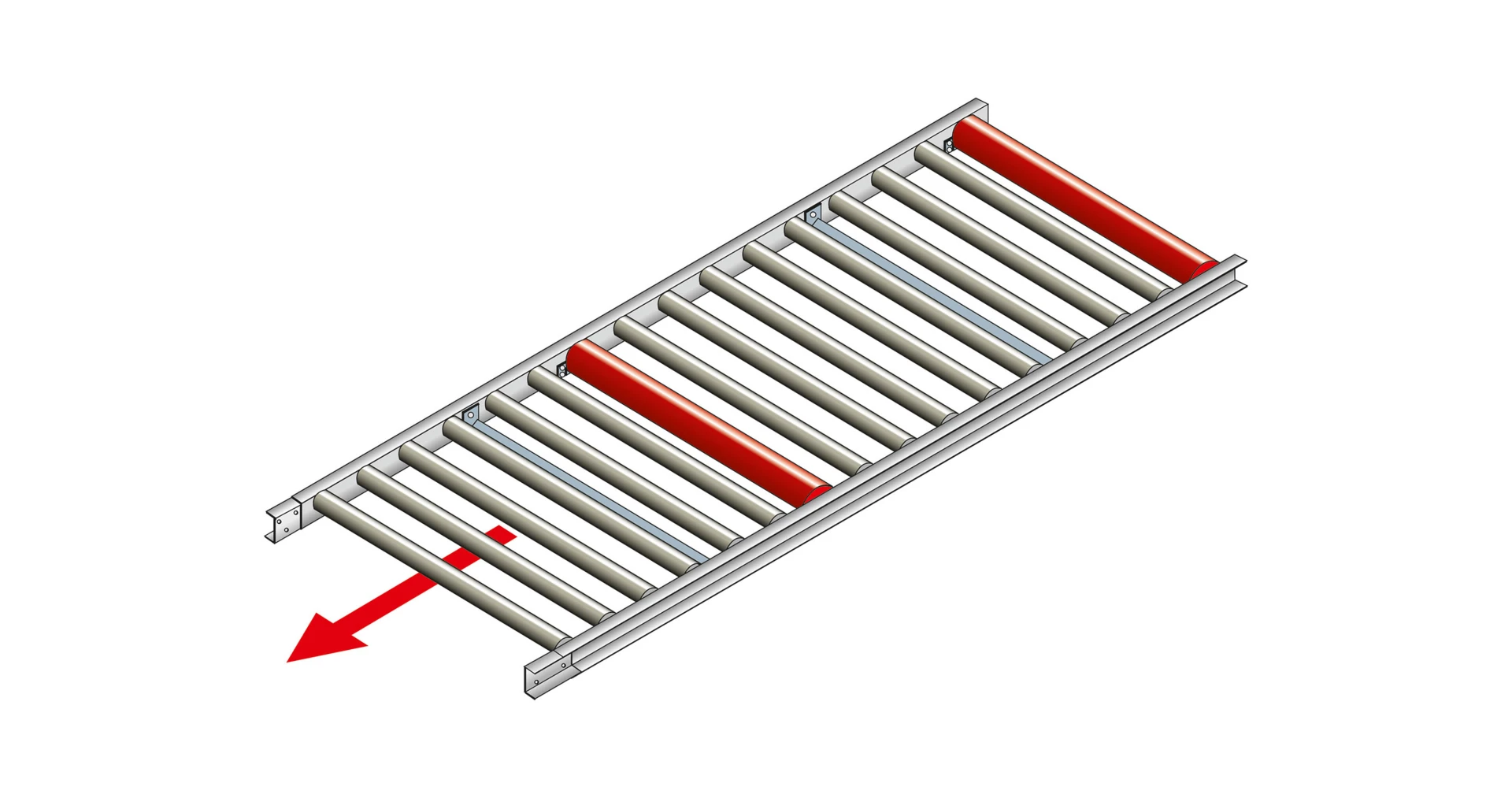

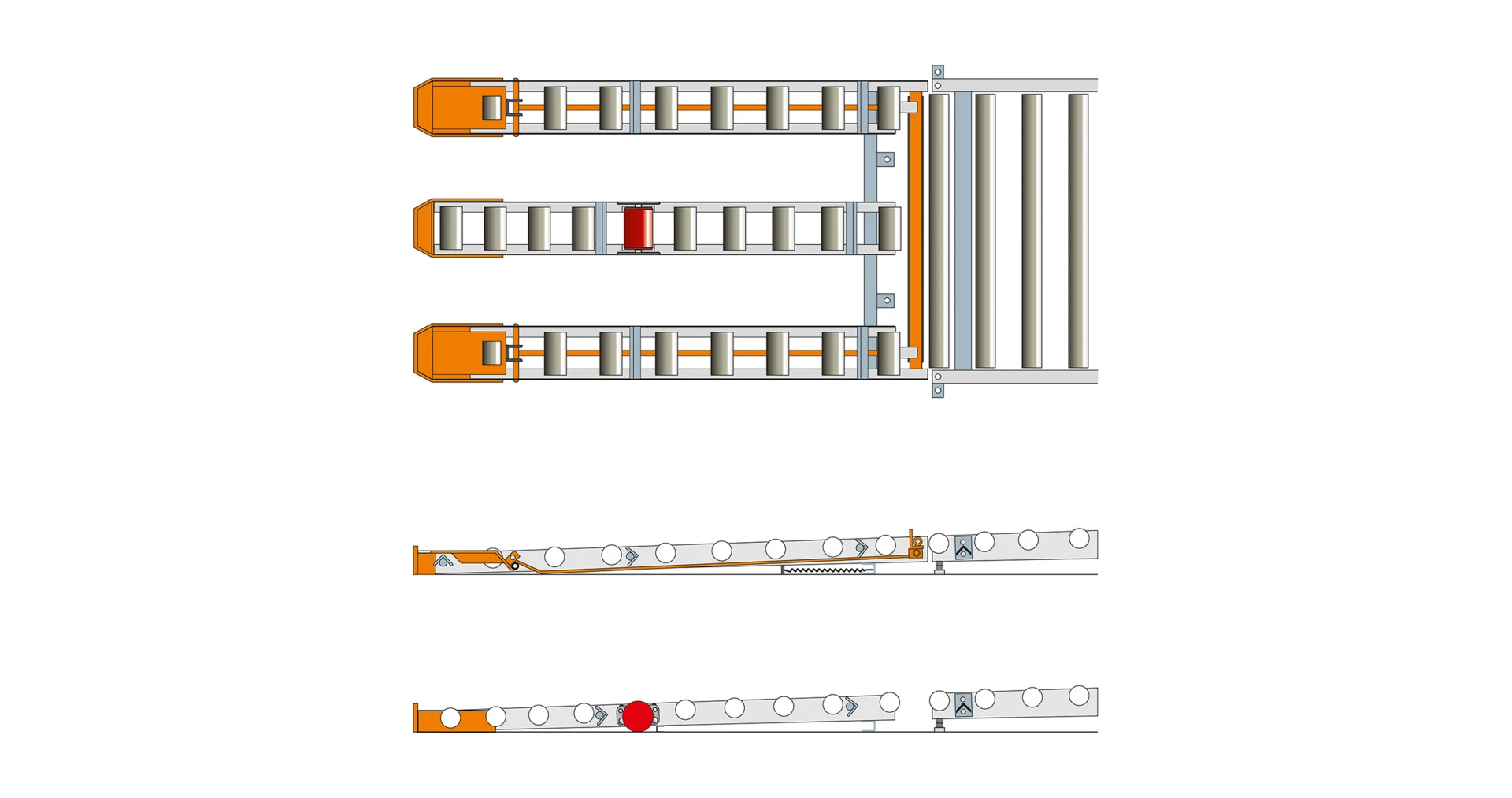

A pallet flow rack mainly consists of rack columns, cross beams and roller tracks. The roller tracks are attached to the columns with an inclination of approx. 4%. The loading section, the central component and the retrieval system with a separator are the three main components of the roller track.

The entry funnel of the loading section ensures that the pallet is placed precisely on the roller track and flows smoothly down the track. Brake rollers ensure that the pallet runs safely through the rack. In order to allow easy retrieval of the pallets without "loading pressure", a separator is attached to the retrieval system, which separates the first pallet in the rack from the other pallets that are inside the channel.

The standard components of the pallet rack (rack column and cross beams) form the frame of the pallet flow rack. The roller tracks are mounted on the cross beams.

Roller for roller tracks

Rollers in roller tracks safely move the pallet through the rack. Each roller in the track has a load capacity of 240 kg. To ensure a long service life they are fitted with a reliable set of steel ball bearings. The bearings as such are maintenance-free. The standard rollers have a steel surface, optionally they are available with galvanised surfaces. Galvanising protects the steel from corrosion.

Loading section with entry funnel

The entry funnel is particularly stable to prevent damage in tough everyday use. In addition, the entry funnel ensures that the pallet is placed centrally on the roller track to allow the pallet to flow as smoothly as possible down the channel. The rollers in the feed-in area are additionally protected by heavy steel plates.

Central component

The roller track profile is made of U- or L-shaped profiles. The low-friction rollers are made of steel, on request they can be galvanised. Each pallet stop is fitted with a brake roller.

Brake roller

Brake rollers reduce the speed of the pallets flowing through the rack. Without brake rollers, the pallets would slip out of the end of the rack.

Retrieval system with separator

A reliable separator at the retrieval point makes pallet retrieval safe. It separates the first pallet in the rack from the others. If one pallet is removed, the next automatically moves forward for retrieval.

3-part floor level rack exit with pallet separator

The 3-part floor level rack exit serves to provide the pallets for transport with a hand pallet truck. A side guard protects the roller track against damage.

Reinforced roller guards

On request the rollers can be additionally protected in the feed-in area by steel plates.

Side reach guard

Side reach guards are mounted on the side of the rack with flowing pallets to protect the channel from access over the side. This provides higher work safety.

Wheel stop

The wheel stop in front of the rack helps stopping the feeding truck at a defined distance in front of the rack. This prevents damages from the rack.

A warehouse planned for efficiency guarantees high economic feasibility. Benefit from the professional consultation with our STILL experts right from the start of warehouse planning. Before you make a buying decision, we assist you in every aspect – from checking your warehouse design to discussing the planned workflows. There are many reasons why you should decide for STILL when buying a rack:

- Many years of expertise: Close to our customers for more than 95 years.

- Partnership that you can rely on.

- Holistic premium concept – from consultation to service.

- Always close to you: 14 branches, 37 rental branches & 800 service technicians in Germany alone.

- A trained installation team ensures proper assembly of your pallet flow or push back racks.